Latraps Agriculture

Tractors, Rapeseed, and Digitalization

Some facts

-

5 281

trucks processed in 2019 -

22 006

trucks processed in 2020 -

20 038

trucks processed in 2021. ~23% applied with the mobile phone

- Human interview excluded from the process

- Automatized entry and leaving with the fiscal document automatically printed from the terminal

- Average processing time improved by 2 minutes which allowed to process 185 trucks more at the same time

- The system is fully adopted. Front line employees are happy because they can do more in less time

- Management is happy because they have data to back up decision-making

- Reduced human contact during the COVID-19 pandemic

- Increased serviced vehicle output per day during high season and avoided public roads jamming

It all started 4 years ago in the city of Eleja near Latvian-Lithuanian border when we met Mr. Mārtiņš Dauksts – technical director of Latraps, the largest agricultural cooperative in the Baltic States.

Mārtiņš is a rare kind of man, a hardworking visionary who dedicated half of his life to developing 10 Latraps elevators across Latvia, building new storage and grain dryers. In Mārtiņš’s vision, Latraps is a completely automated company, where truck drivers self-check-in and self-check-out via smartphone app.

Goals were set

- Automate entry to Latraps territory to speed up the service, improve driver experience and remove driver disputes

- Minimize human involvement in the service process to increase throughput and reduce operational costs

- Gather analytical data to create KPIs and to use it for end-user presentations

- Record photo evidence of the truck number plate and weight readings for dispute resolution

- Digitize paper tickets used for truck management to reduce error margin and gather service data about every service step

- Automate leaving of Latraps territory to speed up the service process

- Develop iOS and Android mobile apps where truck drivers can pre-fill data to avoid crowding at the company entrance, which was increasing service time

Mārtiņš contacted various companies. Only to find out that they don’t have a solution. Then Mārtiņš met Leyline.

After 6 months of meetings, process analysis, and brainstorming we had deconstructed Mārtiņš's vision into the outcome-oriented tasks:

-

Project was divided into two stages. Each stage was to be developed and implemented during the low season (January – May) and put to the test during the high season (June – September).

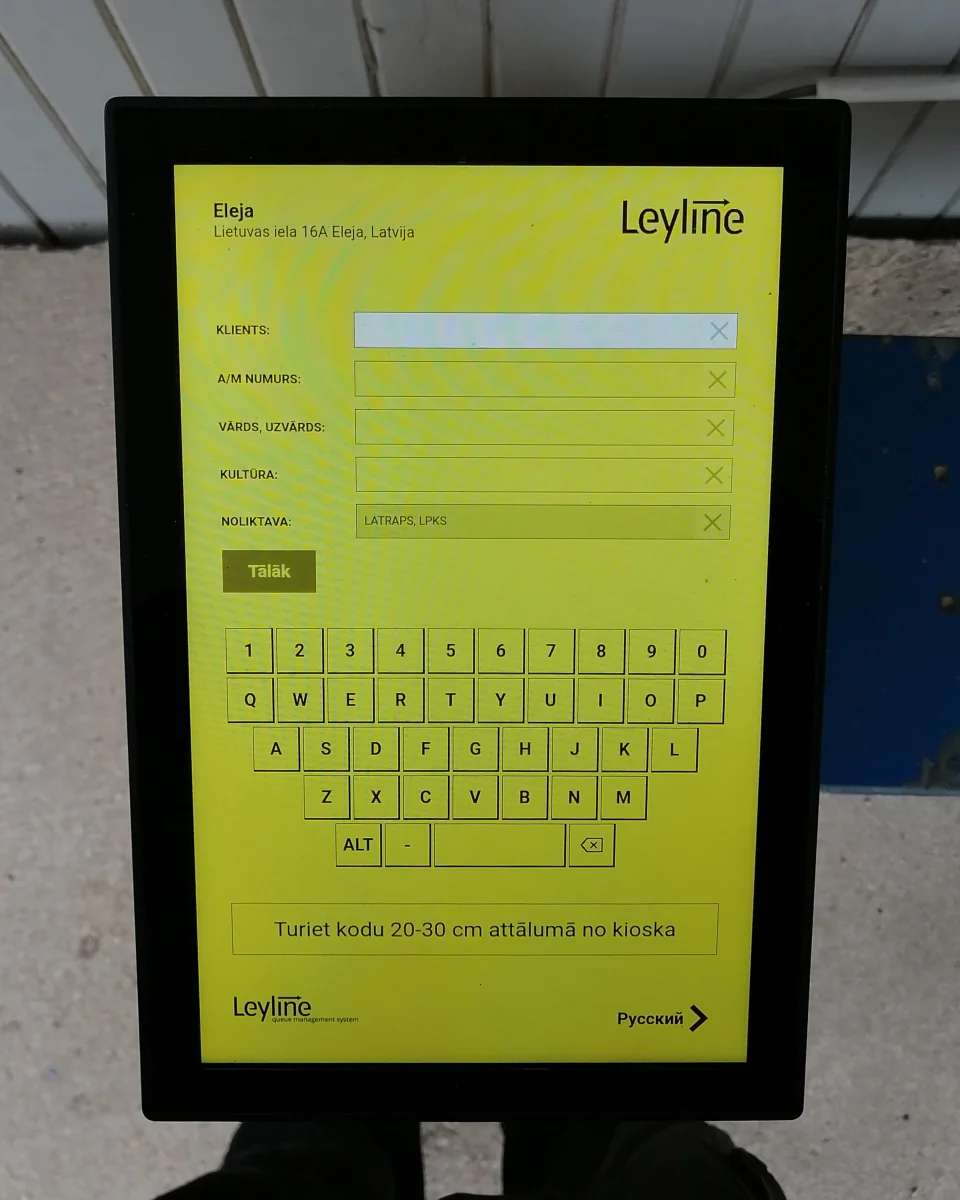

The main concern was the adoption of the new system by the end-user. To decrease the uncertainty, it was decided to create detailed video and pictorial tutorials for the end-users and start gradually building awareness. Video tutorial is publicly available here (in Latvian):

Project stages

- 2019 2020 1st stage

-

- Developing of photo-proof system and installation of video cameras

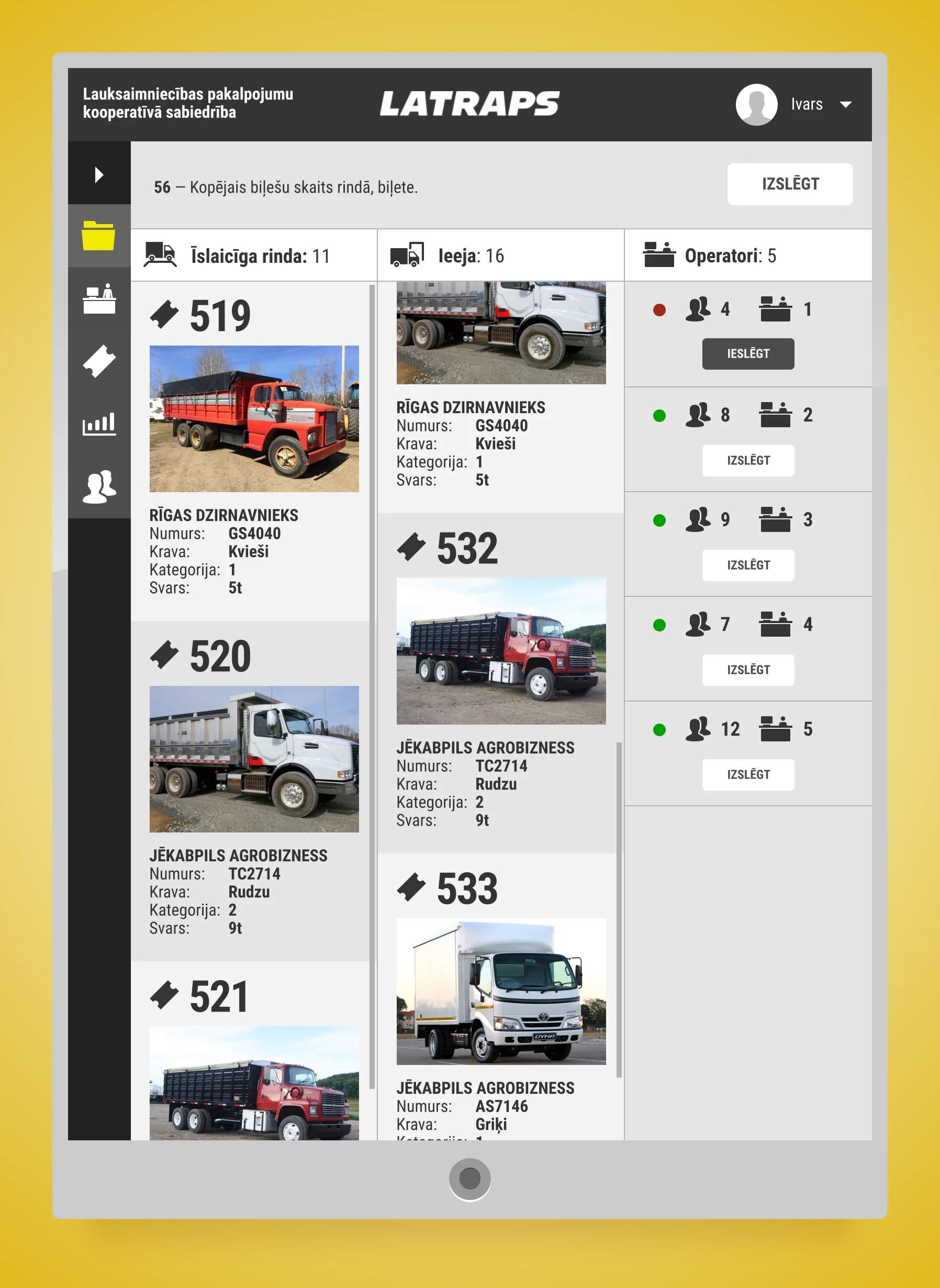

- Installation of self-service kiosks with a barcode scanner to identify arriving and leaving clients

- Development of custom interfaces for laboratory workers and pit operators

- Leyline integration with Latraps ERP

- Leyline integration with Scales

- 2021 2nd stage

-

- iOS mobile app development

- Android mobile app development

- Integration with the existing systems

-

-

Process:

This plan disrupted the decade-long established processes, affecting ten grain complexes with hundreds of employees across Latvia. To improve new system adoption, training videos and detailed instructions were developed and implemented by Latraps.

-

-

Added 9 points

Latvia

- Aizkraukle

- Barkava

- Bauska

- Daugavpils

- Eleja

- Jaunpagasts

- Jekabpils

- Madona

- Saldus